|

Quick

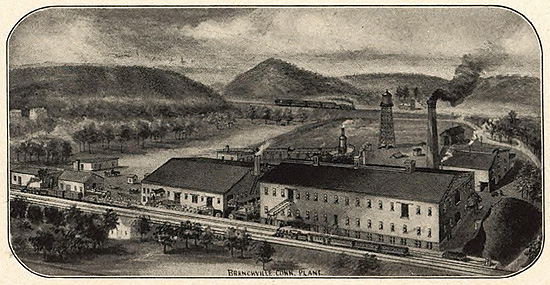

Link: Pictures of Branchville

; DeBenigno's

Store ; Branchville in the News

What the corner

of Route 7 and Route 102 used to look like.

Ancona's

Market celebrates 87 years of memories

From

"Branchville's Birth" by Jack Sanders December 30,

1986.

Branchville, first

applied in 1870 to the southeast corner of town(Ridgefield),

was named for the "branch" rail line from the Danbury

and Norwalk Railroad to Ridgefield Village. The first recorded

use of the term appears in an 1870 deed for four acres "lying

in the town of Ridgefield at Branchville."

It was the very

same year that the branch line was built, suggesting that

the railroad rather than neighborhood residents had invented

the name to distinguish the station from the new one at Ridgefield

center. Previously, the station at Branchville had been known

as Ridgefield Station.

Passenger service

on the branch line was available into town until 1925; freight

service lasted until 1964. Most of the trackbed, complete

with gravel but missing its rails, is today the path of the

Northeast Utilities high voltage line. Some of the other sections

along southern Florida Road have been sold to adjoining landowners.

To the Indians,

the southeast corner of town was known as Wheer Cock. Later

it was called Copps Corner. When the railroad line from Norwalk

to Danbury was completed in 1852, the neighborhood was at

first called Beers Station or Ridgefield Station, after the

stop there.

While this area

had been mostly farmland and a mill or two, the coming of

the railroad sparking the development of a booming, albeit

small-scale, industrial community. It included mills, stores,

a hotel, a machinery factory, a noted mineral quarry, a post

office, and a school (the schoolhouse, still standing on Old

Branchville Road, has in recent years been used by the Jaycees

as a meeting hall).

Branchville had

its own school district at own school district at least since

the middle 19th Century-it was known as the "Ridgefield

Station District" before it was called Branchville. Its

schoolhouse was used until around 1927 when children started

being "bused" to Garden School on Bailey Avenue

in the village. A new Branchville School opened in 1969 on

lower Florida Road, remained in use until 1983 when it was

closed due to declining enrollments.

An 1893 atlas labels

this territory as "Plattsville," which is undoubtedly

a mapmaker's error. The U.S. Geological Survey map uses "Branchville

Hill" for the ridge along Old Branchville Road at Bruschi

Lane.

A map prepared

for the town assessors in 1934 labels as Branchville Hill

road what we today call Nod Hill Road. This suggest that the

ridge traversed by this road was at some time called Branchville

Hill, a more likely possibility than the Branchville Hill

situation cited above.

Railroads Influence

on Branchville/Georgetown area

By Brent M. Colley

By the mid-to-late

1870's, The D&N was competing against several other companies

including the New York, New Haven & Hartford and the Housatonic

Railroad. The D&N sought an advantage in freight traffic by

building a rail and ferry connection on Long Island Sound

at Wilson's Point in South Norwalk in 1882. That extension

of the transportation system allowed for an excellent intermodal

connection between steamships and freight cars ready to move

goods inland or ship raw materials like ice, quarried stone,

and wire products to the ports of New York City.

The Wilson Point

extension proved to be very profitable for the D&N and made

the D&N Railroad an attractive business partner for other

rail lines including the Housatonic Railroad and the New York,

New Haven & Hartford. The extension proved to be even more

profitable for the businesses located on the D&N rail line.

The timing could not have been better for the Gilbert & Bennett

Manufacturing Co., they had recently incorporated as a joint

stock company to overcome their losses via a fire that destroyed

their upper factories and now as a result of the RR expansion

had direct access to worldwide ports, not to mention a spur

line running directly into their warehouses. Branchville businesses

profited as well…the discoveries at Fillow's Mine attracted

businesses and geologists from far and wide to create a local

mining industry that would continue into the 1940's. The Union

Porcelain Works of Greenpoint, New York was the first to arrive

in 1880 to mine for quartz and feldspar and as a result of

the RR expansion had instant access to a booming freight line.

Ridgefield Granite Works, that we'll discuss below, had been

in business since the initial RR line was laid and now had

access to larger markets as well.

And as we all know

the success of businesses, creates jobs and attracts employees…employees

have families, families have needs and therefore with the

next wave came the businesses that "service" these needs.

In almost "textbook" fashion the towns of Branchville and

Georgetown flourished with the introduction and improvements

of the D&N railroad.

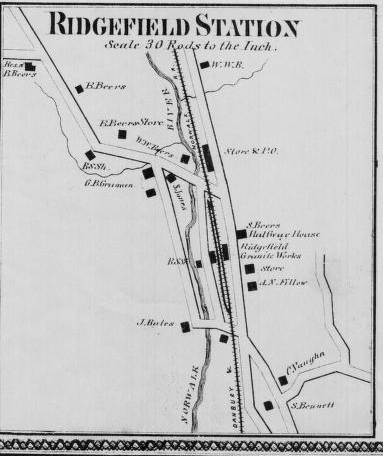

Ridgefield/Branchville

Station in the 1850's

The

Branchville Mine & The Mining History of Branchville:

by Brent M. Colley (Mining

Document if you missed the Mining Tour in May)

Abijiha

N. Fillow's Branchville Mica Mine was by-far the "magnetic

force" that attracted mining companies and geologists to the

area. However, as the map above shows 20 years prior to the

discoveries at Fillow's mine, Philo Bates' Ridgefield Granite

Works was operating out of the station area. In land records

regarding properties on Mountain Rd., Philo W. Bates is listed

in 1875 as owning land "East" of 32 Mountain Rd. and in 1890

as conveying a 20 acre parcel to Abijiha Fillow at 34 Mountain

Rd. which would place at least a portion of his mining areas

on Mountain Rd. and in the areas of the Scott Preserve/Rock

Lot.

Little

is known about the Ridgefield Granite Works aside from the

1856 Clark's Map reference and land records of properties

owned by Philo W. Bates but it is presumed that it was a successful

business given the span of time it operated in the area. Also

appearing on the 1856 station map as a business is Walter

Bates, mason and builder, which very likely involved a joint-venture

with the Granite Works.

The

"World Famous" Branchville Mica mine lies in the town of Redding

on Mountain Road, 550 ft. N.E. of the Branchville railroad

station.

The

first excavation in the Branchville Mine was made about 1876

by Abijiha N. Fillow, then owner of the property. Fillow was

mining for mica. The mica recovered was then considered of

inferior quality, and operations ceased sometime before the

spring of 1878. At that time, George J. Brush and Edward S.

Dana, both of Yale University, became so enthused about the

new minerals at Branchville that they engaged Fillow to excavate

the deposit with funds furnished by Yale.

The

results of these excavations gained the mine worldwide fame

as (9) rare minerals (eight were discovered for the first

time in the history of science) were mined at this unique

location:

(A)

Lithiophilite, maganese-iron phosphate, its name indicates

its lithium content.

(B) Natrophilite, sodium-manganese phosphate, its name indicates

a high sodium content.

(C) Dickinsonite, hydrated acid phosphate of sodium and manganese.

Named in honor of Rev. Dickinson, formerly of Redding, CT.

(D) Fillowite, a hydrated acid phosphate of sodium, manganese,

iron and calcium. Named in honor of A.N. Fillow of Branchville,

CT

(E) Fairfieldite, a hydrated phosphate of calcium. Named in

honor of Fairfield, CT

(F) Eosphorite, a hydrated basis phosphate of aluminum with

iron and manganese. Named from the Greek in allusion to its

pink color.

(G) Reddingite, hydrated phosphate of manganese and iron.

Named in honor of Redding township.

(H) Tripoidite, basis phosphate of manganese and iron. Named

in allusion to its resemblance to triplite in physical character

and composition.

Information

regarding these minerals appeared in scientific journals from

1878 to 1890 launching Brush and Dana's careers and one would

hope- Fillow's real estate property value.

The World

Famous Branchville Mica Mine Today (2006)

In

1880 the Union Porcelain Works of Greenpoint, New York, bought

the property from Fillow and operated it for feldspar and

quartz until 1891. The principal use for feldspar was in the

ceramic industry. Other uses included enameling for metal,

glazes, and abrasives in soaps. At this time the mine was

renamed "The Smith Mine". Fillow stayed on as supervisor of

mining operations but resigned one year later. As a stipulation

in the sale, all unused minerals were to be placed at the

disposal of Brush and Dana.

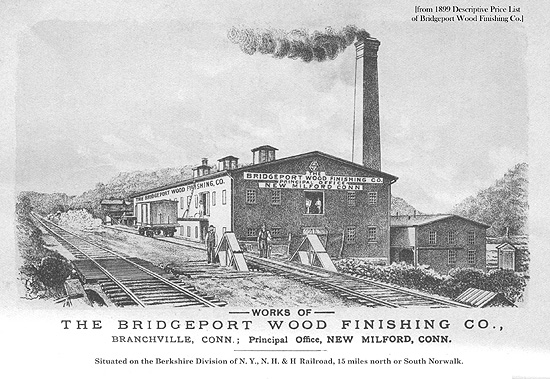

Next

the Bridgeport Wood Finishing

Company of Bridgeport & later New Milford, Connecticut,

operated for quartz and feldspar at the mine as well as other

locations in the Branchville area from 1891 to 1917. These

"other" areas included Mountain Rd., Pine Mountain Rd. and

parts of the land we now refer to as the Scott Preserve/Rock

Lot. Deeds indicate Jesse Fillow leased a 3-acre triangular

piece to the BWFC at 32 Mountain Rd. in 1911, BWFC transferred

it to Gininone Di Giavanni in 1914. BWFC also leased a 4-acre

tract from John Barrett in 1911 at 34 Mountain Rd. for "the

purpose of searching for quartz or silica; of conducting mining

and quarrying operations and of recovering from here any quartz

or silica…" Details also note "BWFC has the right to renew

this agreement on the same terms and conditions for a further

period of 10 years upon written notice..." the mining operation

called for the removal of 100 gross tons of quartz or silica.

More specifically "if 100 gross tons of quartz or silica are

not mined or quarried, as now contemplated by said parties

within any year during the continuance of this agreement…then

these presents and everything contained therein shall cease

and be forever null and void."

In

1906, historian Charles Burr Todd wrote: "There is

a large frame building standing just across the track from

the quarry on the line of the branch road leading to Ridgefield.

This building...has been erected and furnished with powerful

and costly machinery for the purpose of crushing the quartz,

or, more properly, oxide of silicon, found in the neighboring

hills..."

"Silex"

was the trade name for quartz sand, a form of silica BWFC

used extensively in making paste wood fillers; it is chemically

inert, does not absorb moisture or shrink and can be stained

to match any finish. Unfortunately for its workers it was

also extremely damaging to the lungs. BWFC was in business

from 1876 to 1917 when it was purchased by DuPont.

In

addition to Bridgeport Wood Finishing Co. the properties in

and around the mine were leased to several other individuals

and companies in this time frame. For example, a June of 1897

lease between BWFC and William Haaker for 65 acres of land

in Redding and Ridgefield, provided BWFC the right to mine

for quartz and feldspar, and specifically stated that Haaker

only had the right to quarry granite. In 1907 Haaker leased

the same parcel to Traylor Manufacturing and Mining Co. of

New Jersey for the purpose of mining quartz and feldspar for

a period of 5 years. In 1914, Anna Haaker leased the same

parcel to Monarch Mining Co, formerly Traylor Manufacturing

and Mining Company. Traylor Manufacturing and Mining Company

incorporated in 1907 with capital stock of $20,000 and one

year later would increase that stock to $50,000 and change

their name to Monarch Mining Company.

J.

Frank Schairer located 31 different minerals at the mine in

1926. It was part of his research work on "The Minerals of

Connecticut." He collected the data while he was at Yale.

From

September 1943 to November 1944, Fred and Joseph Burrone and

Carlo Rusconi, all of North Branford, Connecticut, operated

the mine for mica, and the Sandy Ridge Mica and Mining Company,

Inc., 927 15th Street N. W., Washington, D. C., worked the

mine in November and December 1944. Also in 1944, detailed

studies of the geology were made as part of the strategic-minerals

investigations of the United States Geological Survey.

Sheet

and scrap were the two types of mica mined. Sheet mica was

used primarily for insulating electrical equipment. Specifically

it was used in spark plugs, lamp sockets, radio apparatus,

fuse boxes, heating devices and telephones.

Scrap

mica was used for roofing, wallpaper, paints, for filler in

rubber such as automobile tires, and lubricants. The demand

for sheet mica during World War II induced operators to work

the long dormant mine in 1943 and 1944.

After1944

the mine was sporadically operated until 1954.

The

last attempt to reopen the mine was made in 1979 by geologist,

Michael DeLuca but his request was turned down by the zoning

commission.

About

Mica:

The

word "mica" is thought to be derived from the Latin word micare,

meaning to shine, in reference to the brilliant appearance

of this mineral (especially when in small scales).

Mica

is found abundantly throughout Asia, Africa, as well as North

and South America. Until the 19th century, mica was quite

rare and expensive as a result of the limited supply in Europe.

However, its price dramatically dropped when large reserves

were found and mined in Africa and South America after the

early 19th century.

Mica

has a high dielectric strength and excellent chemical stability,

making it a favored material for manufacturing capacitors

for radio frequency applications. It has also been used as

an insulator in high voltage electrical equipment.

Specific

varieties of mica include:

- Biotite

- Muscovite

- Lepidolite

- Phlogopite

Mica is a general

term for a large group of minerals, hydrous silicates of aluminum

and potassium, often containing magnesium, ferrous iron, ferric

iron, sodium, and lithium and more rarely containing barium,

chromium, and fluorine. All crystallize in the monoclinic

system, but mica is most commonly found in the form of scales

and sheets. All the micas have an excellent basal cleavage,

splitting into very thin, elastic laminae. Some varieties

are transparent; resistance to heat is high.

Commercially, the

most important micas are muscovite (potassium mica) and phlogopite

(magnesium mica).

Muscovite, the

commoner variety, is usually colorless, but it may be red,

yellow, green, brown, or gray, with a vitreous to pearly luster.

It occurs in granites, syenites, mica schists, and gneisses,

but is most common in pegmatite dikes. It is widely distributed.

Phlogopite varies

in color from yellow to brown, some specimens having a coppery

tint and others being greenish. It occurs in crystalline limestones,

dolomites, and serpentines in Canada, New York, New Jersey,

and Finland.

Mica mining, because

of the necessity of keeping the crystals intact, is a delicate

operation; drills and blasting powder must be used carefully,

if at all. The mined crystals are first “cobbed,” i.e., roughly

trimmed of rock and cut, then split with a hammer into plates,

and further split into sheets with a knife.

Sheet mica is used

as an insulating material and as a resonant diaphragm in certain

acoustical devices.

Scrap and ground

mica is used in wallpaper, fancy paint, ornamental tile, roofing,

lubricating oil, and Christmas-tree snow.

Ground mica is

sometimes pressed into sheets (micanite) that can be used

as sheet mica.

Most of the sheet

mica used in the United States is imported, chiefly from India

and also from Brazil. Synthetic mica was produced in the United

States after intensive government-sponsored research began

in 1946.

About Granite

Granite is the

name used for a variety of light-colored, coarse-grained igneous

rocks. Orthoclase (potassium) feldspar is typically the most

abundant mineral in granite and significant amounts of quartz

and plagioclase feldspar are generally present as well. Minor

minerals include muscovite mica, biotite mica, hornblende

and others.

The coarse grain

size of granite indicates a slow rate of cooling that occurred

below the earth's surface. The insulating effect of the surrounding

rock caused the magma to crystallize very slowly. The slow

cooling allowed the mineral grains adequate time to grow to

a large size.

Because it crystallizes

"at depth" Granite exposed at the surface indicates a location

where deep erosion has taken place.

Granite is a very

strong, durable stone and is used in a variety of ways. Its

attractive appearance makes it useful as an architectural

stone. It is also widely used in monuments, grave markers,

stair treads, counter tops, window sills, street curbing and

other dimension stone uses.

Granite is also

used in the form of crushed stone or aggregate. Granite aggregate

is mainly used for road construction and maintenance, however

there are many other uses which include concrete, landscaping

stone and paving. The U.S. Geological Survey estimates that

granite accounts for about 16% of the United States crushed

stone production, behind limestone and dolomite.

What Created

The Mining Scars Found on Granite Rocks in and around Branchville?

Hand drilling was

the method used by quarry miners to extract granite blocks

from the landscape. Hand drilling helps remove rock three

ways: (1) A rock may be split into chunks of manageable size

by steel drilled into a natural seam; (2) If the steel in

the seam does not split the rock by itself, the hole may be

fitted with the wedge and feathers. The wedge is driven between

the feathers with a hammer until the rock breaks; (3) Finally

a hole may be used to prepare a rock for blasting. In general,

the larger the rocks, the more likely you will use explosives

to move them. Although hand drilling was slow work, it was

a safe and simple way to chisel out granite blocks and/or

prepare the rocks for blasting.

Old drill holes

are now filled with moss (middle of photo along crack)

The driller drives

the steel by methodical hammering and turning. When the hammer

strikes the head of the steel, the bit is forced against the

rock. After each blow of the hammer, the driller turns the

steel slightly and strikes it again. With each blow the bit

chips small amounts of rock that collect in the hole as "drilling

dust." The driller removes the dust by adding water to the

hole, which creates a mud that sticks to the sides of the

steel. To clear the mud, the driller removes the steel and

raps it against the rock. The procedure is continued until

the hole is deep enough; longer steel is substituted as the

hole lengthens.

Lone drill hole

with another one started to the left of it.

The steel is manipulated

with one hand while the other hand hammers (single jacking),

or the steel is manipulated by two hands while another person

hammers (double jacking).

Ambidexterity was

very helpful for the single jack driller because he could

work longer by shifting the hammer from one hand to the other

to distribute the work. In double jacking one or two drillers

hit a drilling steel with large sledge hammers while a holder

turned the steel slightly after each blow. As the hole deepened,

the holder substituted longer steels in a way that did not

interrupt the driller's disciplined rhythm.

Random

Notes on Branchville

Sherman

Beers was paid $600 for the right to cross land by the DNRR

1850. Not bad, most others received from $1 to $100. Beers

family major land owners in Ridgefield/Branchville area. 252

acres at one time.

Ridgefield

or Beers Station originally. Branchline run in 1869-70 resulted

in name change. A train ran up to Branchville several days

(Feb. 22, 1852) before first official train from Norwalk to

Danbury ran on March 1, 1852.

Before

Branchline people were transported to Ridgefield in horse

and buggy. Branch closed to passengers 1925 (cars, highway

improvements), freight 1964, never electrified. Walking trail

now. NU utility lines.

Old

names for Branchville's location: Wheer

Cock, Copps Corner (John Copp, original

surveyor of Ridgefield 1707-08) Beer's Station, Ridgefield

Station.

Comical

story relayed by Jack

Sanders…Branchvillers tried to pull a "switch-a-roo" on

Ridgefield. Signs were created and posted naming Branchville

as Ridgefield and the actual town of Ridgefield as "West Ridgefield"

This did not go over big and lasted a very short time.

West

Branchville Road, is actually Eastern most point of Ridgefield.

At one time Main Street. The name is puzzling to say the least.

Notable

Individuals:

Julian

Alden Weir. Old Beers Farm. 250+ paintings in Branchville.

National Historic Site. Founding member of 10 American painters.

Property retreat for famous artists of the time period. House

enlarged by famous architect Stanford White.

John

Ames Mitchell, Life Magazine, Life's Fresh Air Camp. City

children came for summer get aways. Later Hidden Valley, Branchville

School Location.

Branchville

to Topstone Stretch

Couch's

cut. The Section between Branchville and Topstone was a very

difficult stretch for railworkers. There was quite a bit of

rock to get through and dynamite was about 18 yrs from being

invented. Pick axes and black powder were likely used. Thomas

Couch was a partner in the 19th Century iron foundry at the

north corner of Florida Hill Road and Route 7. Couch's cut

comes from his name.

The

foundry, which received pig iron from Norwalk and turned it

into agricultural tools, sleigh shoes, stoves, and all kinds

of metal parts. The foundry, which operated in the middle

and late 19th Century, was on the site of an old grist and

saw mill . The grist mill had been erected around 1737 by

Peter Burr and had gone through many owners over the years:

One was a Thomas Couch and his wife, Sara, who owned it from

1783 to 1818. Along with his partner, Ebenezer Burr Sanford,

Thomas N. Couch, possibly the elder Couches' son or grandson,

acquired the grist and saw mills around 1831.

When

the foundry was established is not known. There is tradition

that during the Civil War Couch and Sanford configured a cannon

and fired it whenever good news came back from the battlefield.

Ridgefield's

Surveyor: John Copp (1673-1751)

Colonial Jack of All Trades

by Silvio A. Bedini

In

reading about colonial American surveyors, it is apparent

that few if any were professionally trained. For the most

part they were self-taught and pursued other community activities

in addition to surveying, generally a common trade ranging

from farming to shoemaking. An exception was John Copp of

Boston, who fulfilled numerous civic responsibilities not

only in one community, but in two, as well as in his state.

Born in 1673, he was the son of David Copp, one of William

Copp’s nine children and a cordwainer like his father. William

Copp had emigrated from England. David expanded the cordwainer

business, was the ruling elder of the First Church, clerk

of the market, and sealer of leather. He was a surveyor and

adviser to the Boston selectmen on various matters including

laying of bounds for highways and property listings in the

town. David also “was designated by the selectmen to cooperate

with the constable in the suppression of excessive drinking

and disorders in private houses and licensed places of entertainment.”

He was a highly esteemed citizen and bearer at funerals of

the old elite of old Boston, and among his friends was the

Reverend Cottom Mather.

Established

in Many Professions

His

son John Copp moved to Connecticut while in his twenties,

and in 1698 he married the widow Mary Jagger Phelps of Stamford.

Apparently, not long thereafter he was widowed, then married

again three years later to another widow. There were no children

from either marriage.

During

the next few years Copp apparently established himself as

a schoolteacher in Stamford with success, for his name next

appeared in Norwalk in 1701 when a town meeting voted to hire

him as schoolmaster “in case he can be obtained.” The meeting

left the salary open to negotiation of “reasonable termes”

but specified that part of the payment in the amount of 1

pound 55 should come from a tuition charged to the “schollers”

(pupils) with the payment divided equally among them. Copp

accepted the position and taught both day and evening classes.

In

addition to schoolteacher, Copp was also the local medical

doctor. In 1705 he “obtained the recommendation of the selectmen

of Norwalk and applied for a license to practise medicine.”

He was granted a license, and in 1710 or 1711 he was appointed

a surgeon with a Connecticut regiment which was to march to

Port Royal in Canada to engage the French in battle. At a

meeting of the Governor’s Council in New Haven held on July

24, 1711, it was ordered that a letter be dispatched to Copp

“desiring him to attend and go as Doctor in the expedition

against Canada, which letter was drawn and sent accordingly.”

Copp was to be paid six pounds a month for his service out

of the Colony treasury “and that he shall have a suit of the

regimental cloaths, gratis.” If and where and when Copp received

medical training is not known.

Copp

had been trained in surveying by his father, and probably

had accompanied him on some of his field work, and from time

to time engaged in surveying when called upon. When as early

as 1697 Norwalk residents began to become interested in land

to the north of their community which was owned by Indians,

Copp frequently was called upon to survey for members of the

community. The land was high and rocky, but the soil was fertile

and there were more than sixty miles of streams that could

serve future mills. In 1706 and again two years later, he

was asked with others to survey land in the region, but various

difficulties arose and the expeditions resulted in failure.

The

First Purchase

Finally,

working alone in the summer of 1708, Copp managed to draw

up boundaries for a tract of land of 20,000 acres, roughly

in the southern half of the present town of Ridgefield. He

reported back to the Norwalk residents that “we went up to

view said tract of land and upon our diligent endeavour for

a discovery, we find it to be accomodated with upland considerably

good and for quantity sufficient for thirty families, and

as for meadow land it surpasses both in quantity as well as

in quality what is common to be found in larger plantations.”

In September, Copp and two others from Norwalk representing

the first 26 settlers of new community to be named “Ridgfield”

(later changed to “Ridgefield”) paid the Indians £100 sterling

for what was called “the first purchase” of which there were

to be seven more. The purchase having been made, the General

Assembly in session at Hartford in May 1709 appointed Major

Peter Burr of Fairfield, John Copp of Norwalk, and Josiah

Starr of Danbury, to serve as a committee to make a survey

of the tract of land and to lay it out for a town plat, and

to make return to the General Assembly at New Haven in the

following October “of their doings therein, and of their opinion

how many inhabitants the said tract of land may admit and

contain.” After this was done, a grant was made by the General

Assembly in session at New Haven on October 13, 1709.

Copp

was elected recorder or town clerk of the first town meeting

in 1709 and of which his notes of the meeting survive. Although

for a short time in 1714 Copp held title to property in the

new community, he did not hold title to property in the town.

In 1714 he had some land deeded to him which he turned over

to another several months later; it appears that he was acting

merely as a trustee.

During

the first several years of Ridgfield’s settlement, Copp apparently

lived with one pioneer family or another for periods ranging

from days to months at a time while he helped to lay out the

town and its main street. It was to be six rods wide, and

to run north and south along the eastern declivity of the

ridge. On either side of the street, home lots of two-and-one-half

acres were laid out, and in the rear of these, additional

lots of five acres, making a total of seven-and- one-half

acres. Subsequent divisions were made of the plough land,

meadow land, and bogs.

Haphazard

Schooling

Copp

also served as the town’s physician, and as its first schoolmaster,

instructing the children in a small meeting house near the

center of the town. Schooling appears to have been somewhat

haphazard because Copp also had responsibilities in Norwalk

during this period, and it was not until 1721 that the subject

of education was mentioned in the town records. Ridgfield’s

first town meetings were probably held in Norwalk until the

settlement became more permanent and populated. Copp was also

the town clerk for Norwalk from 1708 to 1740. It is likely

that Copp’s records of Ridgfield town meetings were compiled

in Norwalk, his last entry made in 1713, when he was succeeded

as both recorder and schoolmaster by the Reverend Thomas Hauley,

the town’s first minister.

The

settlement of Ridgfield was but one of Copp’s endeavors, for

during the same period he was extremely active in the civic

and ecclesiastical life of Norwalk and of Fairfield County

as well. In 1706, 1716, and 1718-19 he was elected state representative

from Norwalk to the Connecticut General Assembly. In 1711

he was appointed county surveyor and at the governor’s request

he assisted with a 1716 survey to determine the boundary between

Connecticut and New York State. In 1719 he was engaged in

clearing up confusion over the boundaries of the community

of Norwalk. In 1726 he was appointed to a town committee to

present grievances to county officials. Copp also surveyed

the town of Bradford, New York.

Copp

was no less active in Norwalk’s ecclesiastical affairs. He

was a deacon in Norwalk’s First Congregational Church, and

the town records note that in 1723 he was granted a position

of importance, “the second pue [sic] from the pulpitt.” His

wife was placed “in the third pue on the women’s side.” During

the mid 1720s, Copp served on several church committees that

attempted to settle a dispute between the minister and his

parishioners, who were then most of the townspeople. The dispute

became so heated that in 1726 it was voted at the town meeting

to discontinue payment to the minister of his salary. Copp’s

name appeared on the records of Ridgfield in 1739, noting

that he had come to town to attend the installation of the

new Congregational minister, Jonathan Ingersoll, who came

to replace Thomas Hauley, who had died the year before.

In

his will drawn up in 1749, Copp freed his two slaves, Jack

and Sarah, and provided them with support. Copp died on May

16, 1751, at the age of seventy-eight. There are few suitable

memorials to John Copp in either community in which he lived

and worked. Copps Mountain, a name first used in the town

deed of 1721, was given to a ridge in the northern part of

Ridgefield. Along the southern end of this ridge is “Settler’s

Rock,” campsite of the scouting party that set out to survey

Ridgefield in 1708 before the first purchase was made from

the Indians. Of later date, occurring in deeds from 1748,

is Copps Old Line referring to the border between Danbury

and Ridgefield, also Copps Corner in the Branchville section

referring to the boundaries of Ridgefield, Redding and Wilton

at the corner of Mountain Rd. and Peaceable St.

Silvio

Bedini was an Historian Emeritus with the Smithsonian Institution

in Washington, D.C., and a Contributing Editor for the magazine.

Branchville

Making News: Ancona's Market:

2007:

Ancona's Market celebrates 87 years of memories

2006:

Fruits of their labor: Third generation keeps family business

thriving

By BOB CHUVALA | Fairfield

County Business Journal

It

may not seem very old when put alongside Ridgefield’s 300-year

history, but at 86 years and now in its third generation,

Ancona’s Market is the town’s oldest family-run business.

Actually,

that’s quite an accomplishment because only 30 percent of

family businesses make it to the second generation, said Priscilla

Cale, director of the Family Business Program at the University

of Connecticut in Storrs. UConn recently gave Ancona’s

Market a Family Business of the Year award for not only

surviving, but thriving over the past eight-plus decades.

“My

father started in business about 1920 just 1,000 feet from

where we are now,” said 62-year-old John Ancona who, with

his 73-year-old brother, Joseph, are second-generation owners

of the market in Ridgefield’s Branchville section. But like

many families, exact dates and details can be fuzzy. “1920

is the date we’re using,” Ancona said of the founding.

The

senior Ancona immigrated here from Sicily with his father

and brothers shortly after the turn of the last century, working

in the local Gilbert & Bennett wire in World War I.

“When

he came back he put enough money together to start a small

business,” Ancona said -- a general store of sorts, with a

soda fountain, dry goods, groceries, even a gasoline pump

outside.

Ancona

and his three brothers and one sister lived over the store

as their father expanded his grocery business and holdings

and opened a liquor store.

In

1949 their father constructed a brick building to house a

hardware store; the building survives (The Video Cinema; H&R

Block), the business doesn’t. The grocery business moved into

the building in 1960.

The

elder Ancona died in 1958, and the family business passed

to oldest sons Joseph, then 24, and Nano, then 26. For the

next several decades, the second generation operated the grocery

and liquor stores. “Nano ran the liquor business and Joseph

and I concentrate on the grocery business,” Ancona said.

Flexibility

and innovation

In

1980, both businesses moved into a new 24,000-square-foot

building the Anconas built on Branchville Road property adjacent

to the brick building that faces Route 7. Since then, “we

put in some additional space, bumping out a bakery in 1983

or 1984, and putting on another addition in 1987,” Ancona

said. Today, the store is about 30,000 square feet, half the

size of a contemporary supermarket like Stop&Shop.

The

late Nano’s wife, Carol, and son, Mitchell, own and run the

liquor business, while “Joe and I each have a child working

in the business,” he said. Actually, he said, “they’re not

children any more.” His daughter, Gina, is 30; Joe’s son,

JR, “is 43 or so.”

What

caught UConn’s attention, however, is not the family history,

but how the family tailored the business to meet changing

times and tastes. The annual UConn award has five criteria,

Cale said -- success, positive family and business linkage,

multigenerational family involvement, contribution to the

community and industry, and innovative business practices

and strategies. “

A

lot of family businesses sometimes find it hard to separate

themselves from what they’ve done in the past,” Cale said.

But the Anconas “separated themselves from what was not working,”

she said. “The hardware store wasn’t working, so they closed

that.” And successful family businesses exploit their competitive

advantage of flexibility. The Anconas “listen to their customers

and read the market, and they do that extremely well.” The

family added a bakery and a kitchen, for example, “before

anyone else did.”

Back

in 1978 Ancona’s added a kitchen and started selling fried

chicken and baked ziti, Ancona said. “Not too many other grocery

stores did that then,” he said. The cooked meal offerings

continued to expand to include roast turkey and prime rib,

“all the side dishes” and, six months ago, pizza. “We make

our own dough.”

The

prepared meals menu continues to grow to meet demand. “Everybody’s

on the go these days, and time is very valuable to people,”

Ancona said. “Our prepared meals are as good or better than

they can make at home, and that’s what they opt for.” “

That’s

the kind of innovation we look for,” Cale said.

Succession

planning

The

Anconas have one more advantage in that they recognize something

else about family businesses.

“Some

family businesses see succession planning as a transaction,”

Cale said. “It’s not. It’s a process and it takes a long time

to do. It’s very difficult to transfer the knowledge about

how a business should be run.”

Some

family businesses don’t survive to subsequent generations

because of market conditions and the economy, others because

they don’t have a competitive advantage, she said. But most

fail to survive because of a lack of planning, “particularly

succession planning.” And failure for family business to go

on to the second generation is the norm. “

In

Connecticut there are about 90,000 family businesses,” Cale

said. “About 60 percent of all jobs are created by family

business, but only 30 percent of the businesses make it to

the second generation.” Assuming a family business lasts one

generation or about 30 years, “only 20 percent of the jobs

will survive the transition in those 30 years.”

That’s

one of the things that makes Ancona’s Market so remarkable

-- its survival into the third generation as a thriving, growing

business with about 60 employees, half of them full time.

“To be that long lasting is definitely a generational thing,”

Ancona said. “We’re the second and third generations in house

now, and that’s encouraging.”

Read

more great Fairfield County business stories at: http://www.fairfieldcbj.com

Back

to TOP | Back to Redding

Section | Back to Georgetown

Section

|