|

Quick

Links: The

Rocks,

The Soil, Branchville

Mine, Redding Garnets

The

Rocks:

The geological character of the town was described as metamorphic

by the Rev. John Dickinson. Granite, porphyritic rock and

especially micaceous schist pre-dominated minerals as are

familiar in such rock as hornblende, garnet, kyanite and tremolite.

One needs not travel far to find Redding's rock outcroppings.

Out the backdoor of most any household you will find the "chiseled"

results of natures splendor. The most dramatic geologic masses

can be seen along the Falls Trail in the Saugatuck River Nature

Reserve, the Great Ledge in Devil's Den, and on "Indian's

Lookout" in The Rock Lot/Scott's Preserve.

On a recent walk

in Devil's Den, local historian Roy Spies explained that the

Wisconsin III glacer halted in this area, and in melting dropped

much of the rock we see here today; existing bedrock was scrapped

of its soil cover as the glacer moved across the land. He

also mentioned that much of the rich soil within the glacer

was washed out to Long Island providing that region with near

perfect soil for planting.

Magnesian limestone

could be found in the western part of town and was said to

be quite pure. The mining of limestone in town took place

in and around Limkiln and Lonetown. Just outside of town off

Route 53 in Bethel, CT a limestone quarry lives on today as

a swimming hole named fittingly "The Quarry". A

rather famous mine can be found on Mountain Road. Here is

a bit of its history:

Branchville

Mica Mine

The

"World Famous" Branchville Mica mine lies in the town of Redding

on Mountain Road, 550 ft. N.E. of the Branchville railroad

station.

The

first excavation in the Branchville Mine was made about 1876

by Abijiha N. Fillow, then owner of the property. Fillow was

mining for mica. The mica recovered was then considered of

inferior quality, and operations ceased sometime before the

spring of 1878. At that time, George J. Brush and Edward S.

Dana, both of Yale University, became so enthused about the

new minerals at Branchville that they engaged Fillow to excavate

the deposit with funds furnished by Yale.

The

results of these excavations gained the mine worldwide fame

as (9) rare minerals (eight were discovered for the first

time in the history of science) were mined at this unique

location:

(A)

Lithiophilite, maganese-iron phosphate, its name indicates

its lithium content.

(B) Natrophilite, sodium-manganese phosphate, its name indicates

a high sodium content.

(C) Dickinsonite, hydrated acid phosphate of sodium and manganese.

Named in honor of Rev. Dickinson, formerly of Redding, CT.

(D) Fillowite, a hydrated acid phosphate of sodium, manganese,

iron and calcium. Named in honor of A.N. Fillow of Branchville,

CT

(E) Fairfieldite, a hydrated phosphate of calcium. Named in

honor of Fairfield, CT

(F) Eosphorite, a hydrated basis phosphate of aluminum with

iron and manganese. Named from the Greek in allusion to its

pink color.

(G) Reddingite, hydrated phosphate of manganese and iron.

Named in honor of Redding township.

(H) Tripoidite, basis phosphate of manganese and iron. Named

in allusion to its resemblance to triplite in physical character

and composition.

Information

regarding these minerals appeared in scientific journals from

1878 to 1890 launching Brush and Dana's careers and one would

hope- Fillow's real estate property value.

The World

Famous Branchville Mica Mine Today (2006)

In

1880 the Union Porcelain Works of Greenpoint, New York, bought

the property from Fillow and operated it for feldspar and

quartz until 1891. The principal use for feldspar was in the

ceramic industry. Other uses included enameling for metal,

glazes, and abrasives in soaps. At this time the mine was

renamed "The Smith Mine". Fillow stayed on as supervisor of

mining operations but resigned one year later. As a stipulation

in the sale, all unused minerals were to be placed at the

disposal of Brush and Dana.

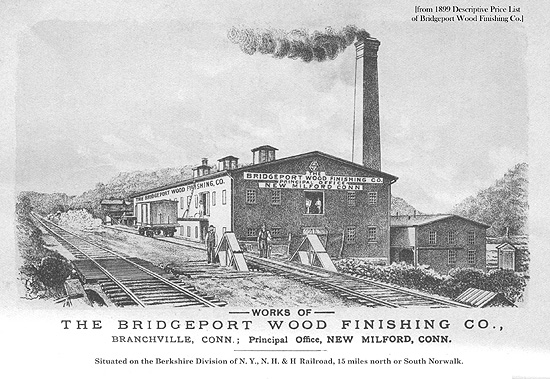

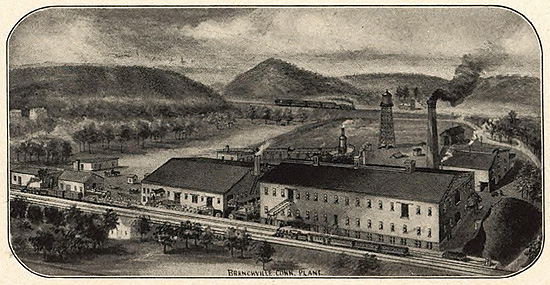

Next

the Bridgeport Wood Finishing

Company of Bridgeport & later New Milford, Connecticut,

operated for quartz and feldspar at the mine as well as other

locations in the Branchville area from 1891 to 1917. These

"other" areas included Mountain Rd., Pine Mountain Rd. and

parts of the land we now refer to as the Scott Preserve/Rock

Lot. Deeds indicate Jesse Fillow leased a 3-acre triangular

piece to the BWFC at 32 Mountain Rd. in 1911, BWFC transferred

it to Gininone Di Giavanni in 1914. BWFC also leased a 4-acre

tract from John Barrett in 1911 at 34 Mountain Rd. for "the

purpose of searching for quartz or silica; of conducting mining

and quarrying operations and of recovering from here any quartz

or silica…" Details also note "BWFC has the right to renew

this agreement on the same terms and conditions for a further

period of 10 years upon written notice..." the mining operation

called for the removal of 100 gross tons of quartz or silica.

More specifically "if 100 gross tons of quartz or silica are

not mined or quarried, as now contemplated by said parties

within any year during the continuance of this agreement…then

these presents and everything contained therein shall cease

and be forever null and void."

"Silex"

was the trade name for quartz sand, a form of silica BWFC

used extensively in making paste wood fillers; it is chemically

inert, does not absorb moisture or shrink and can be stained

to match any finish. Unfortunately for its workers it was

also extremely damaging to the lungs. BWFC was in business

from 1876 to 1917 when it was purchased by DuPont.

In

addition to Bridgeport Wood Finishing Co. the properties in

and around the mine were leased to several other individuals

and companies in this time frame. For example, a June of 1897

lease between BWFC and William Haaker for 65 acres of land

in Redding and Ridgefield, provided BWFC the right to mine

for quartz and feldspar, and specifically stated that Haaker

only had the right to quarry granite. In 1907 Haaker leased

the same parcel to Traylor Manufacturing and Mining Co. of

New Jersey for the purpose of mining quartz and feldspar for

a period of 5 years. In 1914, Anna Haaker leased the same

parcel to Monarch Mining Co, formerly Traylor Manufacturing

and Mining Company. Traylor Manufacturing and Mining Company

incorporated in 1907 with capital stock of $20,000 and one

year later would increase that stock to $50,000 and change

their name to Monarch Mining Company.

Branchville

Mine. Town Road shown to the right is Mountain Road.

Pine Mountain Road now runs to the north of the mine today.

*Sure wish I had a larger version of this map but at this

point this is all that's available.

J.

Frank Schairer located 31 different minerals at the mine in

1926. It was part of his research work on "The Minerals of

Connecticut." He collected the data while he was at Yale.

From

September 1943 to November 1944, Fred and Joseph Burrone and

Carlo Rusconi, all of North Branford, Connecticut, operated

the mine for mica, and the Sandy Ridge Mica and Mining Company,

Inc., 927 15th Street N. W., Washington, D. C., worked the

mine in November and December 1944. Also in 1944, detailed

studies of the geology were made as part of the strategic-minerals

investigations of the United States Geological Survey.

Sheet

and scrap were the two types of mica mined. Sheet mica was

used primarily for insulating electrical equipment. Specifically

it was used in spark plugs, lamp sockets, radio apparatus,

fuse boxes, heating devices and telephones.

Scrap

mica was used for roofing, wallpaper, paints, for filler in

rubber such as automobile tires, and lubricants. The demand

for sheet mica during World War II induced operators to work

the long dormant mine in 1943 and 1944.

After1944

the mine was sporadically operated until 1954.

The

last attempt to reopen the mine was made in 1979 by geologist,

Michael DeLuca but his request was turned down by the zoning

commission.

About

Mica:

The

word "mica" is thought to be derived from the Latin word micare,

meaning to shine, in reference to the brilliant appearance

of this mineral (especially when in small scales).

Mica

is found abundantly throughout Asia, Africa, as well as North

and South America. Until the 19th century, mica was quite

rare and expensive as a result of the limited supply in Europe.

However, its price dramatically dropped when large reserves

were found and mined in Africa and South America after the

early 19th century.

Mica

has a high dielectric strength and excellent chemical stability,

making it a favored material for manufacturing capacitors

for radio frequency applications. It has also been used as

an insulator in high voltage electrical equipment.

Specific

varieties of mica include:

- Biotite

- Muscovite

- Lepidolite

- Phlogopite

Mica is a general

term for a large group of minerals, hydrous silicates of aluminum

and potassium, often containing magnesium, ferrous iron, ferric

iron, sodium, and lithium and more rarely containing barium,

chromium, and fluorine. All crystallize in the monoclinic

system, but mica is most commonly found in the form of scales

and sheets. All the micas have an excellent basal cleavage,

splitting into very thin, elastic laminae. Some varieties

are transparent; resistance to heat is high.

Commercially, the

most important micas are muscovite (potassium mica) and phlogopite

(magnesium mica).

Muscovite, the

commoner variety, is usually colorless, but it may be red,

yellow, green, brown, or gray, with a vitreous to pearly luster.

It occurs in granites, syenites, mica schists, and gneisses,

but is most common in pegmatite dikes. It is widely distributed.

Phlogopite varies

in color from yellow to brown, some specimens having a coppery

tint and others being greenish. It occurs in crystalline limestones,

dolomites, and serpentines in Canada, New York, New Jersey,

and Finland.

Mica mining, because

of the necessity of keeping the crystals intact, is a delicate

operation; drills and blasting powder must be used carefully,

if at all. The mined crystals are first “cobbed,” i.e., roughly

trimmed of rock and cut, then split with a hammer into plates,

and further split into sheets with a knife.

Sheet mica is used

as an insulating material and as a resonant diaphragm in certain

acoustical devices.

Scrap and ground

mica is used in wallpaper, fancy paint, ornamental tile, roofing,

lubricating oil, and Christmas-tree snow.

Ground mica is

sometimes pressed into sheets (micanite) that can be used

as sheet mica.

Most of the sheet

mica used in the United States is imported, chiefly from India

and also from Brazil. Synthetic mica was produced in the United

States after intensive government-sponsored research began

in 1946.

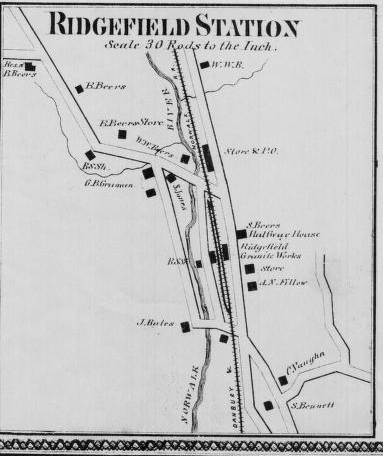

Ridgefield/Branchville

Station in the 1850's

Granite

Mining in Branchville:

Abijiha

N. Fillow's Branchville Mica Mine was by-far the "magnetic

force" that attracted mining companies and geologists to the

area. However, as the map above shows 20 years prior to the

discoveries at Fillow's mine, Philo Bates' Ridgefield Granite

Works was operating out of the station area. In land records

regarding properties on Mountain Rd., Philo W. Bates is listed

in 1875 as owning land "East" of 32 Mountain Rd. and in 1890

as conveying a 20 acre parcel to Abijiha Fillow at 34 Mountain

Rd. which would place at least a portion of his mining areas

on Mountain Rd. and in the areas of the Scott Preserve/Rock

Lot.

Little

is known about the Ridgefield Granite Works aside from the

1856 Clark's Map reference and land records of properties

owned by Philo W. Bates but it is presumed that it was a successful

business given the span of time it operated in the area. Also

appearing on the 1856 station map as a business is Walter

Bates, mason and builder, which very likely involved a joint-venture

with the Granite Works.

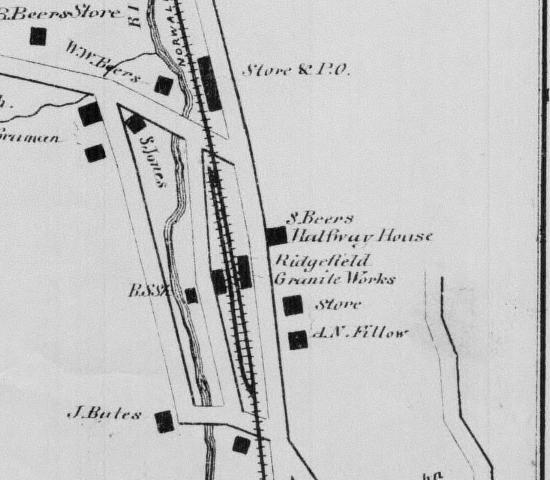

Fillow's

home or business shown in the 1850's down on what is now West

Branchville Road. This map is a close up of Branchville Station

(branchline would come in 1870). Road running behind A.N.

Fillow is Mountain Road. The business next to Fillow is of

interest, Ridgefield Granite Works, location of busines may

shed some light on who was responsible for the

mining evidence up in the Scott's Preserve/Rock Lot.

About Granite

Granite is the

name used for a variety of light-colored, coarse-grained igneous

rocks. Orthoclase (potassium) feldspar is typically the most

abundant mineral in granite and significant amounts of quartz

and plagioclase feldspar are generally present as well. Minor

minerals include muscovite mica, biotite mica, hornblende

and others.

The coarse grain

size of granite indicates a slow rate of cooling that occurred

below the earth's surface. The insulating effect of the surrounding

rock caused the magma to crystallize very slowly. The slow

cooling allowed the mineral grains adequate time to grow to

a large size.

Because it crystallizes

"at depth" Granite exposed at the surface indicates a location

where deep erosion has taken place.

Granite is a very

strong, durable stone and is used in a variety of ways. Its

attractive appearance makes it useful as an architectural

stone. It is also widely used in monuments, grave markers,

stair treads, counter tops, window sills, street curbing and

other dimension stone uses.

Granite is also

used in the form of crushed stone or aggregate. Granite aggregate

is mainly used for road construction and maintenance, however

there are many other uses which include concrete, landscaping

stone and paving. The U.S. Geological Survey estimates that

granite accounts for about 16% of the United States crushed

stone production, behind limestone and dolomite.

What Created

The Mining Scars Found on Granite Rocks in and around Branchville?

Hand drilling was

the method used by quarry miners to extract granite blocks

from the landscape. Hand drilling helps remove rock three

ways: (1) A rock may be split into chunks of manageable size

by steel drilled into a natural seam; (2) If the steel in

the seam does not split the rock by itself, the hole may be

fitted with the wedge and feathers. The wedge is driven between

the feathers with a hammer until the rock breaks; (3) Finally

a hole may be used to prepare a rock for blasting. In general,

the larger the rocks, the more likely you will use explosives

to move them. Although hand drilling was slow work, it was

a safe and simple way to chisel out granite blocks and/or

prepare the rocks for blasting.

Old drill holes

are now filled with moss (middle of photo along crack)

The driller drives

the steel by methodical hammering and turning. When the hammer

strikes the head of the steel, the bit is forced against the

rock. After each blow of the hammer, the driller turns the

steel slightly and strikes it again. With each blow the bit

chips small amounts of rock that collect in the hole as "drilling

dust." The driller removes the dust by adding water to the

hole, which creates a mud that sticks to the sides of the

steel. To clear the mud, the driller removes the steel and

raps it against the rock. The procedure is continued until

the hole is deep enough; longer steel is substituted as the

hole lengthens.

Lone drill hole

with another one started to the left of it.

The steel is manipulated

with one hand while the other hand hammers (single jacking),

or the steel is manipulated by two hands while another person

hammers (double jacking).

Ambidexterity was

very helpful for the single jack driller because he could

work longer by shifting the hammer from one hand to the other

to distribute the work. In double jacking one or two drillers

hit a drilling steel with large sledge hammers while a holder

turned the steel slightly after each blow. As the hole deepened,

the holder substituted longer steels in a way that did not

interrupt the driller's disciplined rhythm.

Redding

Garnets from "The Rock Hound" Redding Times,

1955

Some of the finest

garnets in Connecitcut came from a garnet vein in Redding.

A Mr. Lloyd writing to the editor of the Amercian Journal

of Science dated Weston Conn. May 27, 1820 says: "Garnet

Rock or the precipice in and about which Garnets are found

in abundance and perfection is situated one mile and a half

south of the Congregational Meeting house in the Town of Redding

and about one half mile west of the junction of the two large

branches of the Saugatuck River, which unite a short distance

above the south boundary of the Town of Redding. The northwest

branch of the Saugatuck River runs a winding course in a southerly

direction at the foot of the hill on the top of which are

the rocks under consideration. On top of the hill and at the

base of these rocks on the south east side the Garnets will

be seen by the most inattentive observer, projecting from

the rocks in a manner resembling musket balls shot halfway

into a board."

These large red

garnet crystals are not as easy to find today as they were

in 1820. This is due in part to man's development of the river

areas in this vicinity and the destruction of some of the

better collecting grounds.

Fine cinnamon brown

garnet crystals are also found in Redding and could be seen

in museums and private mineral collections all over the world.

The various well-colored,

transparent garnets are cut as gem stones, the rough granets

are used as an abrasive.

Ronald E. Januzzi

The

Soil:

The Redding area

experienced glaciation in recent geologic time(1.5 million

years ago) the last glacier believed to have receded 10 to

15 thousand years ago according to Former Wetlands Officer

for the Conservation Commission, Stanley Schleifer.

New England soils are very close in composition to their parent

rock. This is due largely to the fact that weather and vegetation

has not had adequate time to breakdown the minerals as it

has in unglaciated regions. Minerals are as prevalent in the

soil as they are in the bedrock that has yielded it. The topsoil

layer that exists averages a depth of 2 1/2" to 8",

a depth that would be suitable for agriculture if not for

the boulders and larger rocks scattered through it. Some areas

contain a sub-soil that makes cultivation possible. This topsoil

mixes with approximately 10 centimeters of sub-soil

and gives the appearance of a thicker soil than actually exists.

Soil is generally thought of as a mixture of particles of

three different sizes: sand, silt, and clay. In New England,

however, we cannot overlook the particles larger than sand

size, such as pebbles, stones, and cobbles. Although these

larger particles do not contribute very much to the physical

and chemical properties of the soil, they do play a crucial

role in determining whether or not the soil is fit for agriculture,

no matter how suitable it is otherwise.

When sand, silt, and clay are present in about equal amounts,

the soil is known as loam. Usually, one or another predominates

and the soil is then further classified as sandy loam, silt

loam, or clay loam.

Southern New England is now about 60 to 75% woodland. Most

of the soils are too sandy, stony, or wet for cultivation.

In fact, probably less than 15% of the area now in woodland

is potential cropland.

Soil maps of most of southern New England resemble intricately

sewn patchwork quilts, showing soils often of widely differing

properties existing in close proximity. Such a condition makes

modern farming almost impossible.

Click below

to continue on reading about the landscape:

Farms

Bodies of Water

Geologic

Back

to TOP | Back to Redding

Section | Back to Georgetown

Section

|